Sections single-spindle drilling, sawing and thermal cutting

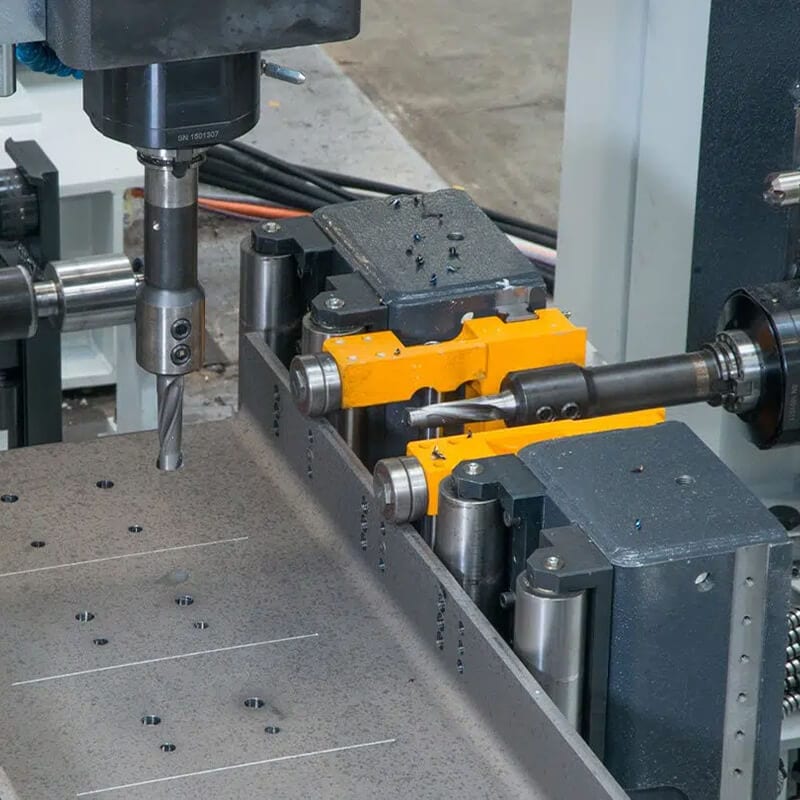

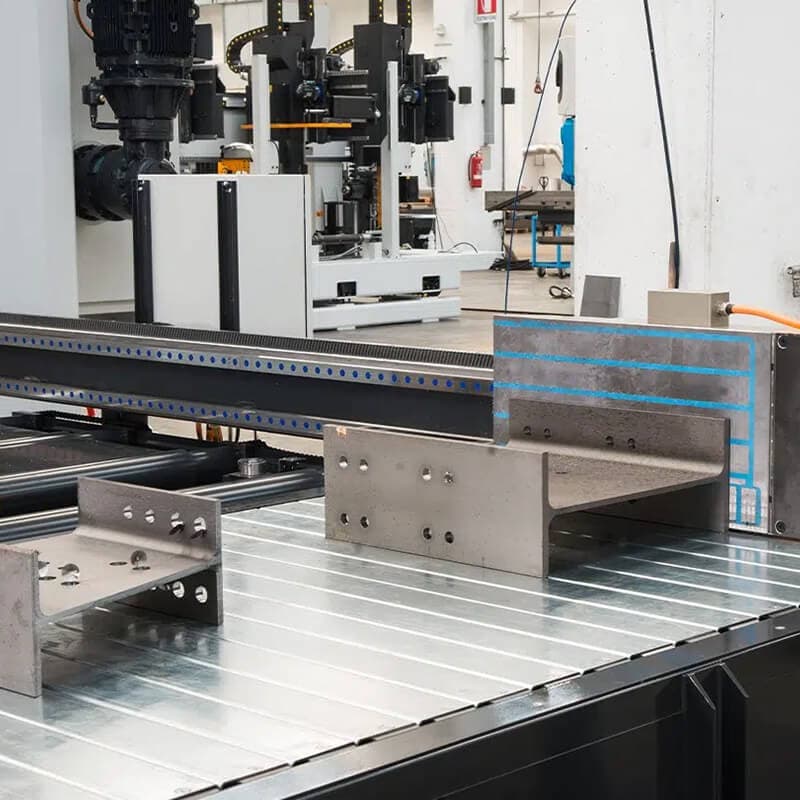

Automatic CNC drilling, drilling & band sawing, drilling & coping lines for sections. The Orient is a CNC controlled beam drilling line with a single rotating spindle which can process both flanges and the web. Orient is the evolution of a simple and efficient concept developed by Ficep over 40 years ago. Its versatile engineering allows various operations normally available on most multi spindle drilling lines.

A sophisticated combination of probing, clamping and laser devices allows precise measuring of the beam length and width, as well as the flanges and web height.

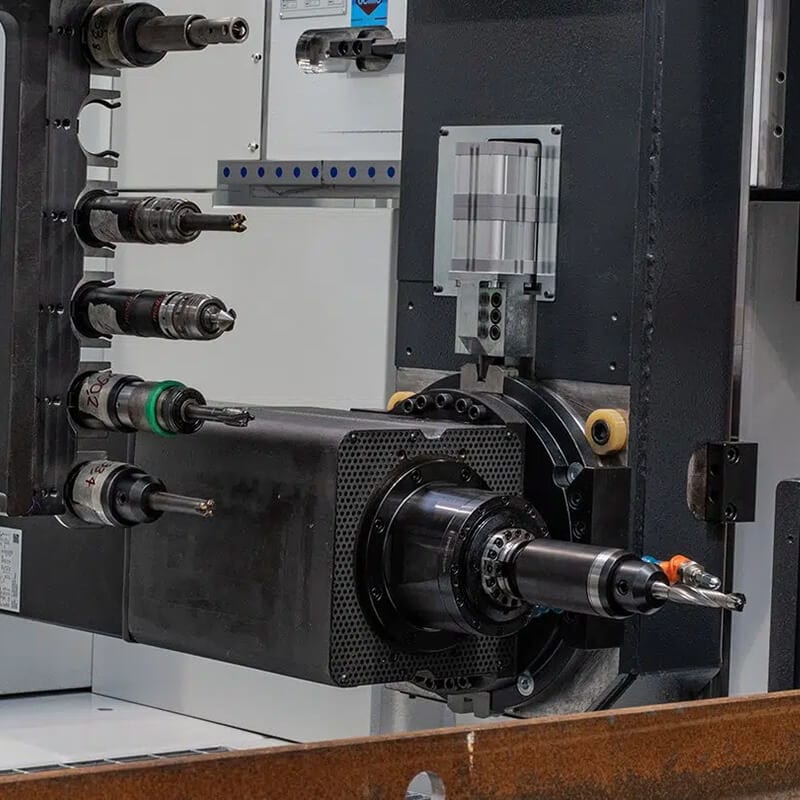

The rotating spindle can process both flanges and the web with extremely reliable performances.

The powerful direct drive spindle ensures high drilling performances. This heavy duty, yet simple design, makes this spindle the most efficient and advanced on the market today.

The Orient can be equipped with an additional spindle to boost its performance even more.

Thanks to the high RPM range of the spindle carbide tools can be utilized to their maximum efficiency.

Besides the top scribing, carried out with the relevant tool, underside scribing operations can be performed with an optional scribing spindle.

The automatic tool change system is managed by the CNC and is equipped with 6 positions.

When combined with a band saw, a magnetic back fence allows for the unloading of trim cuts, small drops and short parts onto the unloading table for short pieces.

When combined with a band saw or with a thermal coping robot, there is no need to add an additional CNC unit as the entire system is controlled by a single CNC.

All our systems are supplied in accordance with the highest safety standards and regulations.

| Orient | Section size [min. mm] | Section size [max. mm] | Drilling heads [no.] | Drilling tools per head [no.] | Drilling diameter [max mm] | Spindle power [kW] | Spindle speed [max.RPM] | Machine weight [kg] |

|---|---|---|---|---|---|---|---|---|

| 451 OR / 451 OR-R | 60* x 10 | 460 x 460 | 1 (2) | 6 (12) | 40 | 31 | 5000 | 8500 |

| 601 OR / 601 OR-R | 60 x 10 | 610 x 460 | 1 (2) | 6 (12) | 40 | 31 | 5000 | 9500 |

| 1001 OR / 1001 OR-R | 60 x 10 | 1015 x 460 | 1 (2) | 6 (12) | 40 | 31 | 5000 | 9500 |

| 1101 OR / 1101 OR-R | 80 x 10 | 1115 x 510 | 1 (2) | 6 (12) | 40 | 31 | 5000 | 10000 |

| 1201 OR / 1201 OR-R | 80 x 10 | 1220 x 610 | 1 (2) | 6 (12) | 40 | 31 | 5000 | 10000 |

* Angles, square and rectangular tubes with min. side of 50 mm only on carriage and pincher feeding models.

| Orient | Motor power [kW] | Band saw blade speed [max.mt/min] | Band saw blade size [mm] | Machine weight [kg] |

|---|---|---|---|---|

| 451 ORB | 9 | 170 | 41 x 1.3 x 7250 | 13000 |

| 601 ORB | 9 | 170 | 41 x 1.3 x 7250 | 14000 |

| 1001 ORB | 9 | 170 | 41 x 1.3 x 7250 | 14000 |

| 1101 ORB | 15 | 170 | 54 x 1.6 x 9920 | 21500 |

| 1201 ORB | 15 | 170 | 67 x 1.6 x 9000 | 16400 |

| Orient | Oxy-fuel-fuel torch [no.] | Plasma torch [no.] | Machine weight [kg] |

|---|---|---|---|

| 602 ORFRC | 1 | 1 | 18500 |

| 602 ORRAZ | - | 1 | 18500 |

| 1202 ORFRC | 1 | 1 | 19000 |

| 1202 ORRAZ | - | 1 | 19000 |