Depending on your cutting tool, we offer a suitable product for sawing your billets before extrusion.

GLOBE offers biodegradable lubricants of vegetable origin to be applied by micro-lubrication (MQL minimum quantity lubrication) on the saws to prepare the billets before the heating and extrusion operations.

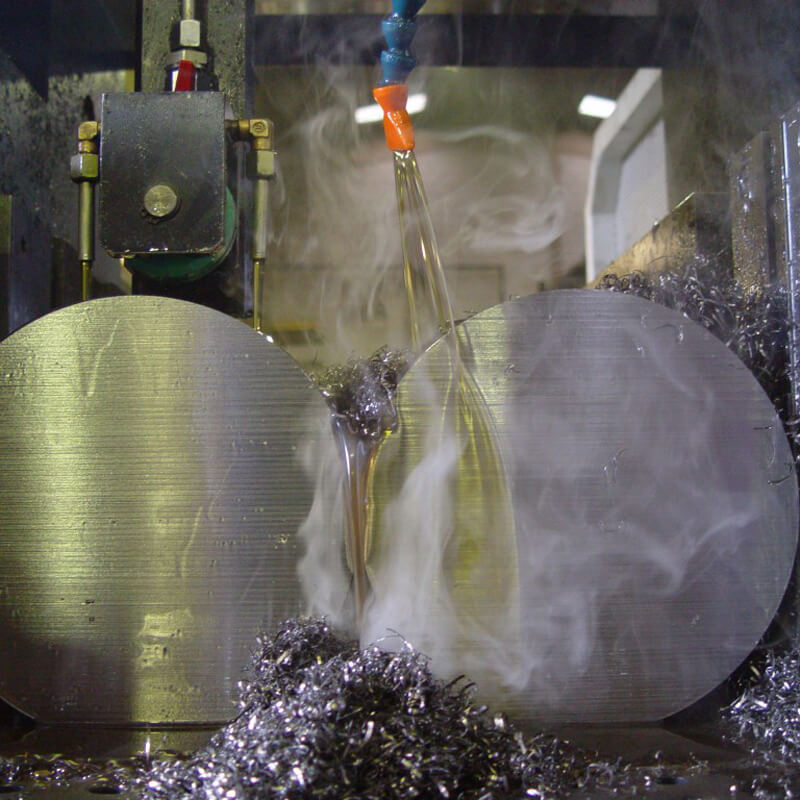

Thanks to its expertise in machining fluids, GLOBE has a complete range of vegetable cutting oils to be applied to the knives or saws to cool and lubricate them during cutting of aluminium billets.

With their vegetable base, they replace traditional petroleum or mineral based lubricants, while favouring an eco-citizen approach. These concentrates are used pure and are compatible with all ferrous and non-ferrous metals.

For cutting extruded profiles, GLOBE offers emulsions of lubricating agents to be applied to the cutting tools to cool and lubricate them and avoid sticking of the aluminium profiles as they exit extrusion.

These silicone emulsion based products are beneficial replacements for traditional petroleum-based lubricants. Their specific chemistry allows them to be used over a wide range of temperatures, while avoiding clogging or stains and providing protection against corrosion. The chemistries used are entirely compatible with subsequent painting.

These concentrates should be diluted in water before use: generally between 1 and 4 %.

For the protection of guillotine-type tools, we also offer products containing a dispersion of boron nitride in water or a solvent, depending on your production constraints.

Globe CondaluK is a high-performance, water-based extrusion lubricant. Globe CondaluK allows the cooling and lubrication of tools.